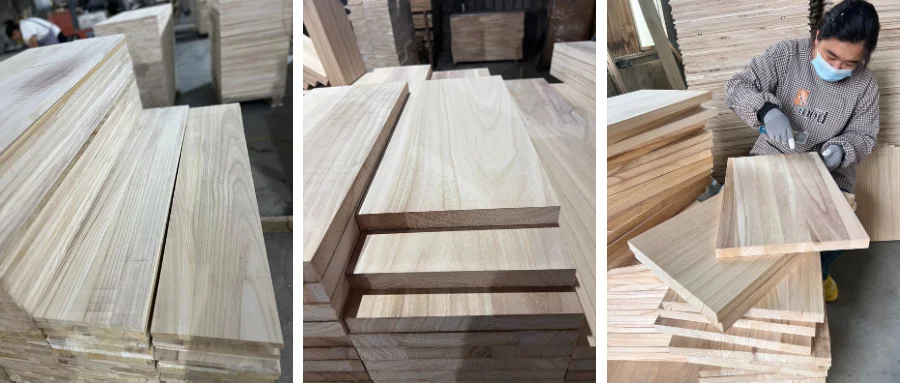

Paulownia Wood Factory: Solving Your Pain Points with Our High-Performance Planks

As a source factory (Shandong Paulownia Wood Source Factory)specializing in paulownia wood planks with 15 years of experience, we’ve heard every complaint from furniture makers, renovators, and buyers: “Hardwood is too costly,” “Planks warp easily,” “Production is inefficient.” Today, we’re here to prove—paulownia wood isn’t just a material; it’s the solution to these industry headaches. From raw material sourcing to finished product delivery, we control every link, ensuring our paulownia planks turn your pain points into profits.

Problem 1: High production waste & low efficiency? Paulownia’s performance cuts through it. Unlike hardwoods that splinter, knot, and resist cutting (causing 15%+ material waste), our paulownia planks have inherently straight, uniform grain—thanks to our strict selection of 5-8 year mature paulownia logs. This means:

① Waste rate drops to 3% (saving you raw material costs);

② Cutting, drilling, and sanding are 40% faster (no more waiting for stubborn grain);

③ Saw blade wear is reduced by 60% (lower tool consumption).

Our long-term partner, reported a 22% increase in monthly output after switching to our paulownia planks—same labor, better results.

Problem 2: Poor stability & frequent after-sales troubles? Paulownia’s stability speaks for itself. The biggest nightmare for manufacturers is planks warping or cracking due to moisture changes—we’ve solved this with two layers of protection:

① Paulownia’s natural low moisture absorption (far better than pine);

② Our proprietary 3-stage kiln-drying process, locking moisture content at 8-12% (meets international standard EN 322).

The result? A return rate of less than 5% for our planks, even in humid Florida or dry Arizona. A Toronto kids’ furniture brand relies on us for play table planks—“Soft edges avoid bumps, and zero warping means zero customer complaints,” their purchasing manager said.

Problem 3: High costs eating into profits? Paulownia’s cost advantage is unbeatable—especially as a source factory.

① Sourcing: We own 10,000 mu of paulownia plantations, so raw material costs are 25% lower than hardwoods (no middlemen markup);

② Pricing: Our paulownia planks are 30% more affordable than pine planks of the same specification, while maintaining solid wood quality;

③ Shipping: Paulownia’s density is only 0.32-0.4g/cm³ (1/3 of oak), cutting your ocean freight costs by 18% per container.

Beyond addressing core issues, the unique properties of paulownia wood (Direct Supply of Paulownia Wood Panels from China)have unlocked further commercial opportunities. Its natural acoustic resonance makes our panels the instrument maker's preferred choice. In acoustic projects, our paulownia boards deliver twice the sound absorption of standard timber, proving ideal for home recording studios and office partitions. Notably, it meets E0 environmental standards (featuring natural antimicrobial properties with zero added formaldehyde) — a prerequisite for today's health-conscious market.

As a source manufacturer, we offer not only panels but bespoke solutions: from 2mm ultra-thin sheets to 50mm thick boards, ranging from natural wood grain finishes to ready-to-use polished products. If you've grown weary of solid wood's drawbacks, pine's high cost, or inconsistent quality—our paulownia panels provide the solution. Contact us immediately for complimentary samples and a custom quotation.