- Browse Categories

- Pine | spruce wood board

- Melamine board

- Rubber wood board

- Poplar board

- Paulownia wood board

- Carbonized wood board

- Subscribe

-

Get email updates on new products

- Hot Products

- Contact Us

-

Contact Person : Sarah

Job Title : sales Director

Business Phone : +86 15806737107 Contact Now

Custom Width Heat Treated Poplar Strips

- Products name:carbonized poplar wood

- Glue:E0, E1 Standard Environmental Glue

- Board Details:

- 1) Weight: 300KG/CBM

- 2) Moisture: 8%-12%

- 3) Thickness Tolerance : <0.1mm

- 4) Width/Length Tolerance : <2.0mm

Product Overview

Carbonized poplar(Carbonized Poplar Strip Supply) is a kind of modified wood after high-temperature carbonization treatment, using high-quality poplar as raw material, and under high-temperature environment for pyrolysis treatment, so that the physical and chemical properties of the wood change, thus obtaining more excellent performance.

Characteristics

Environmentally friendly and healthy: Carbonized by physical methods, without adding any chemicals, non-toxic, harmless, safe and environmentally friendly, in line with international environmental standards.

Anti-corrosion and anti-insects: The high temperature environment effectively kills the fungi and insect eggs in the wood, destroying their living environment, giving the wood excellent anti-corrosion and anti-insect properties, and prolonging its service life.

Stability and Durability: The carbonization process reduces the moisture absorption of the wood, improves dimensional stability, and makes it less susceptible to deformation and cracking, making it suitable for a wide range of climatic conditions.

Natural texture: Carbonized wood has a clearer and more natural texture, soft color and unique decorative effect, and can be carbonized to different depths to obtain different color effects according to demand.

Easy to maintain: The surface of carbonized poplar wood is treated to be easy to clean and maintain, only need to apply wood wax oil regularly to keep its beauty and performance.、

( Heat-treated Poplar Strip Factory)

Application

Due to its excellent performance, Poplar Carbide is widely used in the following areas:

Interior decoration: flooring, wall panels, ceiling, furniture, stairs, doors and windows, etc.

Outdoor landscape: floor, fence, flower box, pavilion, wooden house, water-friendly platform, etc.

Other fields: handicrafts, musical instruments, packaging materials, etc.

Product Specification

The specifications of Carbonized Poplar (Heat-treated wood factory) can be customized according to customers' requirements, common specifications include:

Thickness: 15mm, 20mm, 25mm, 30mm, etc.

Width: 90mm, 120mm, 140mm, 160mm, etc.

Length: 900mm, 1200mm, 1500mm, 1800mm etc.

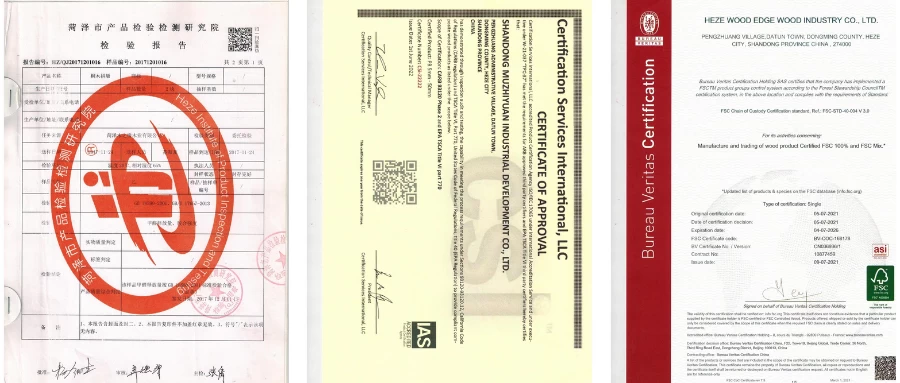

Our certification

Tel:+86 15806737107

Wechat:S15806737107

Facebook:https://www.facebook.com/Linkedinwoodwork/

Contact Person:Sarah

PDF Show:PDF